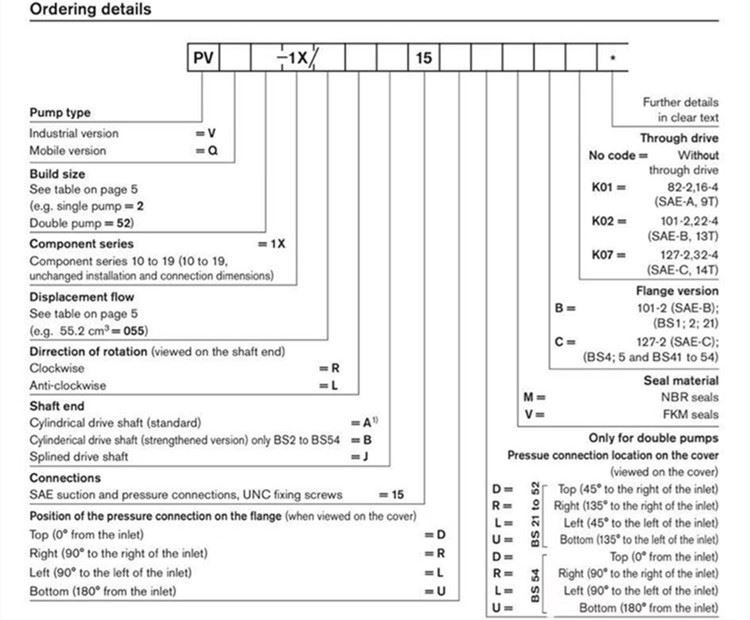

Hydraulic Fixed Displacement Vane Pumps PVV Series Cutting Machine Hydraulic Punch Press Oil Pump PVV5-1X/162RJ15DMC

| Hydraulic fixed displacement vane pumps PVV Series cutting machine hydraulic punch press oil pump PVV5-1X/162RJ15DMC |

| Data sheet |

| Maximum operating pressure 210 bar |

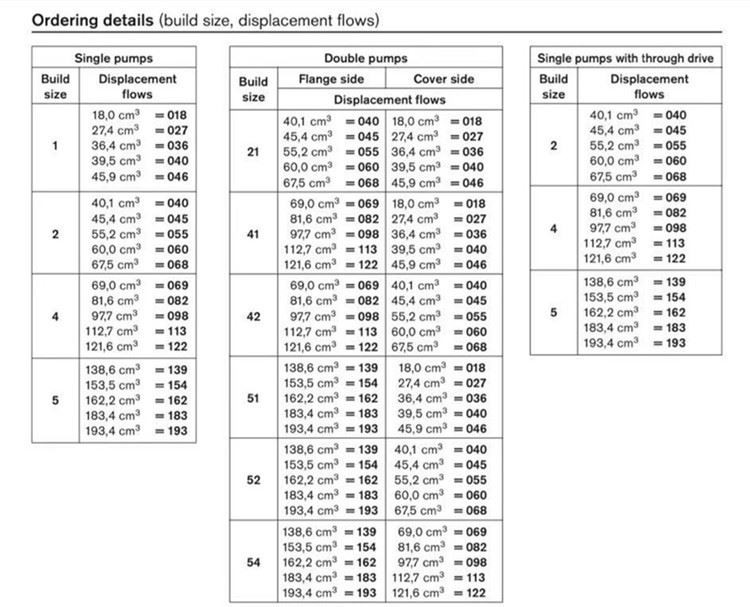

| Maximum displacement 18 to 193 cm3 |

| The rotor is fitted onto the splines of the drive shaft which rotates inside the stator ring. The vanes are fitted into slots in the rotor and are pressed onto the inner surface of the stator ring by centrifugal force as the rotor turns. The displacement chambers are sealed on the sides by the control plates. Due to the double extentric form of the stator ring there are two pressure and two suction chambers opposite to each other. The drive shaft is thereby hydraulically unloaded. It only has to carry the torque forces. The vanes are partially unloaded as they pass through the suction areas. This unloading results in reduction in wear and makes it possible to obtain a high efficiency. |

Hot Tags: Hydraulic Fixed Displacement Vane Pumps PVV Series Cutting Machine Hydraulic Punch Press Oil Pump PVV5-1X/162RJ15DMC, China, manufacturers, factory, customized, wholesale, quotation, low price, in stock, sauer hydraulic motor, H1B fixed displacement motor, rexroth A2F hydraulic motor, Rexroth A2FE Series Hydraulic Motor, H1B bent axis hydraulic motor, sauer danfoss motor